Customize Metal Cosmetic Makeup Display Floor Stand

Zhongshan Yishang Metal Manufacturing Co., Ltd.Base Info

Description

Product NameCustomized cosmetic shop store display rack stand design Technology Laser Cutting, Stamping, Bending, Tapping, Welding, Grinding, etc Material cold-rolled sheet ;

You can also choose aluminum sheet,stainless steel plates, galvanized sheet, etc. Measurement Custom dimensions Color You can choose your favorite color from the RAL color card. Surface Treatment Stainless steel: polished, brushed, sand blasted, sha-steel, etc.

cold-rolled sheet: powder coated, painted, electroplated, etc

Aluminum: oxidation, powder coating, painting Production Time Sample: 3 - 5 days. Batch order: 12 - 15 days. Services Professional custom fabrication metal display stand / display rack services. Services Professional custom fabrication metal sheet services Overall product structure: Long frame, layer frame, small storage cabinet and brake caster combination.

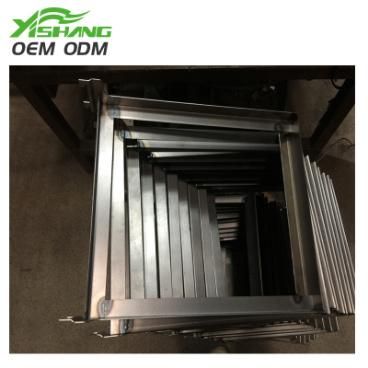

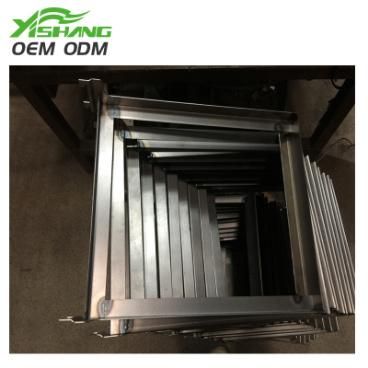

Production process: using laser cutting machine and precision CNC bending machine bending molding.

Self-inspection requirements: the use of laser cutting machine can cut any plane graphics, no need to open a mold. High cutting precision (+-0.1) small cutting burr.

CNC bending Angle (within +-50c), length, width (within +-20c), surface scratch, no damage, no shadow, components assembled seamless, straight, consistent hole.

layer frame:

Adopt 1.0 mm thickness cold rolled iron plate processing and forming. Installation method: the installation method is fixed in the hole of the back plate of the exhibition frame by means of clasp.

Cheap customer disassembly and installation.

At the bottom:

1. Locker: The metal tube is screwed together to the bottom. At the bottom of our design is a small storage cabinet, in which you can put spare stock products.

2. Pulley:

1) brake pulley: flat or inclined ground are applicable, can be moved at will, but also firmly fixed in position.

2) ordinary pulley: it is only applicable to the flat and straight ground. Although it can be moved at will, it is not conducive to the fixation of the display frame.

Packing method: Polybag: mainly adopts PO or PE polybag.

Type: ordinary plastic bag - large integrated display rack conventional use of unsealed ordinary plastic bag, easy to take out the display rack. Airtight bag - airtight bag for accessories or small products to prevent goods from falling through the mouth of the bag.

Foam: polyolefin foam with a density of 7kg/m and a thickness of 30mm is commonly used.

Carton: the use of 5 layers of double corrugated carton, large and very heavy products are recommended to use 7 layers of corrugated carton.

Installation method:

The exhibition frame is not taken apart, the bulk suggested way of assembly, product cost and your installation cost will be reduced, different countries (installation + transportation) costs are relatively different.

You can also choose aluminum sheet,stainless steel plates, galvanized sheet, etc.

cold-rolled sheet: powder coated, painted, electroplated, etc

Aluminum: oxidation, powder coating, painting

Production process: using laser cutting machine and precision CNC bending machine bending molding.

Self-inspection requirements: the use of laser cutting machine can cut any plane graphics, no need to open a mold. High cutting precision (+-0.1) small cutting burr.

CNC bending Angle (within +-50c), length, width (within +-20c), surface scratch, no damage, no shadow, components assembled seamless, straight, consistent hole.

Adopt 1.0 mm thickness cold rolled iron plate processing and forming. Installation method: the installation method is fixed in the hole of the back plate of the exhibition frame by means of clasp.

Cheap customer disassembly and installation.

1. Locker: The metal tube is screwed together to the bottom. At the bottom of our design is a small storage cabinet, in which you can put spare stock products.

2. Pulley:

1) brake pulley: flat or inclined ground are applicable, can be moved at will, but also firmly fixed in position.

2) ordinary pulley: it is only applicable to the flat and straight ground. Although it can be moved at will, it is not conducive to the fixation of the display frame.

Type: ordinary plastic bag - large integrated display rack conventional use of unsealed ordinary plastic bag, easy to take out the display rack. Airtight bag - airtight bag for accessories or small products to prevent goods from falling through the mouth of the bag.

Foam: polyolefin foam with a density of 7kg/m and a thickness of 30mm is commonly used.

Carton: the use of 5 layers of double corrugated carton, large and very heavy products are recommended to use 7 layers of corrugated carton.

The exhibition frame is not taken apart, the bulk suggested way of assembly, product cost and your installation cost will be reduced, different countries (installation + transportation) costs are relatively different.